Single Girder Overhead Crane

| Work Load(t) | 1-20t (Customizable) |

| Span(m) | 7.5-35.5m (Customizable) |

| Lifting Height(m) | 6-30 m |

| Work Class | A3/A4 |

| Power Supply | 220V/380V/400V/415V/660V, 50-60Hz, 3-phase ACCrane |

| Control Method | Ground Control/Remote Control/Cab |

| Control Travel Speed | 20-30m/min |

Overview

The single-girder overhead crane is a hoisting equipment that spans the air of workshops, warehouses and yards for material lifting. It is an important tool and equipment to realize mechanization and automation of the production process in modern industrial production and hoisting transportation, and is widely used in indoor and outdoor industrial and mining enterprises, iron and steel chemical industry, railway transportation, ports and terminals, logistics turnover and other departments and places

Advantages of single girder overhead crane

1. Since the design is relatively simple, the freight is reduced, the installation steps are simplified, the installation can be fast, and the materials for bridges and runway beams are reduced, thereby reducing costs

2. It is the most cost-effective choice for light and medium cranes

3. Light weight, thereby reducing the load on the building structure or foundation. Normally, it can be supported by the existing roof structure without using additional support columns

4. Easy to install and maintain

5. Long service life, less wear

6. It is suitable for facilities with low headroom, which reduces the requirements for the use of space

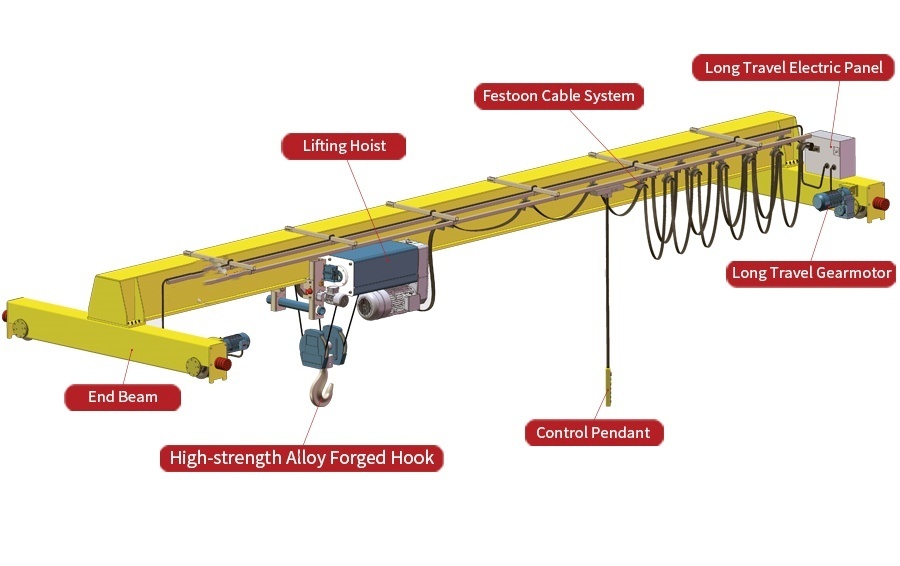

Structure of Single Girder Overhead Crane:

Accessories of Single Girder Overhead Crane:

1.Metal structure components

Including main girders and end girders. The main girder mostly adopts I-steel or a composite section of steel sections and steel plates. The end girder is used to connect the two ends of the main girder and support the entire crane structure.

2.Hoisting mechanism components

Including electric hoists, steel wire ropes, pulleys, hooks, etc. The electric hoist is the core of the hoisting mechanism. The steel wire rope connects the hook, pulley block and drum, the pulley is used to guide the steel wire rope, and the hook is used to bear and lift the load.

3.Traveling mechanism components

Mainly including wheel sets, motors, reducers, couplings, brakes, etc. The wheel sets are installed at the bottom of the end girders and run along the rails; the motor provides power, which is transmitted to the wheels through components such as reducers and couplings, and the brake is used to control the crane's stop.

4.Electrical control components

Including wires and cables, remote controls, travel switches, control boxes, etc. Wires and cables are used to transmit electrical energy, remote controls and control boxes are used to operate the crane, and travel switches are used to limit the movement position or stroke of the crane.

5.Safety protection components

Including overload limiters, bumpers, anti-unhooking devices, etc. The overload limiter can prevent the crane from operating overloaded, the bumper is used to reduce the impact force when the crane collides, and the anti-unhooking device can prevent the load on the hook from accidentally falling off.

Related Cases:

An automotive component enterprise upgraded its production line, needing to solve the efficient transportation problem of 3-8 ton cast iron parts (engine blocks, gearbox housings). The workshop span is 22.5m, requiring adaptation to 380V three-phase power supply, while balancing safety and corrosion resistance requirements.

Equipment Selection:

3 units of LDA-type electric single-girder overhead cranes were selected, with core configurations as follows:

1、Rated lifting capacity: 10t; Span: 22.5m; Lifting height: 12m

2、Duty class: A4; Control mode: Wireless remote control + Ground control (dual-mode)

3、Special configurations: Anti-corrosion coating, overload limiter, travel limiter.

Application Effects:

1、Transportation efficiency tripled: Single-batch time reduced from 15 minutes to 4 minutes, with equipment utilization rate reaching 91%.

2、Safety upgraded: Manual intervention reduced by 80%, achieving zero safety accidents throughout the year.

3、Cost savings: Annual maintenance cost decreased by 67%, saving over 300,000 yuan in labor costs.

4、Strong adaptability: No rust under coolant environment, with failure rate as low as 0.3 times per month.

Application

Single girder overhead crane is an ideal choice for workshops, warehouses, material yards, and manufacturing and production facilities.It is widely used in machining workshops, assembly places, warehouses, goods yards,material stocks.

European Standard Single Girder Overhead Crane :

Europe Standard Single Girder Overhead Crane is the new designed crane for the low workshop and high lifting height demands. It has many advantages such as: strong rigidity, light dead weight, outstanding structure design, etc, It could save your factory space and investment effectively.

Advantages of European standard single girder overhead crane

1. Low headroom and high reliability

2. Take multiple measures to ensure the smooth operation of material handling

3. Faster transportation

4. Have more intelligent functions to help efficient production

5. Support synchronous lifting and centralized control

6. The electrical components are of good quality and durable.

Our Services:

Training:

Modular hands-on training programme

Highly qualified instructors and state-of-the-art equipment

Hands-on tasks to ensure that participants achieve all of their course goals

Training courses held at our training centre or locally

Installation:

Commissioning of crane installations

inspection and approval by our authorised crane inspectors

Spare Parts:

Fault analysis

Repairs carried out on site or at our Repair Center

Provision of genuine spare parts to replace damaged or defective parts

Recommendations for daily maintenance

Repair:

Genuine parts

Unsurpassed reliability

Long service life