Rubber Tired Gantry Crane

| Work Load(t) | 20-800 |

| Span(m) | 5-50 |

| Lifting Height(m) | 6-30 |

| Work Class | A5-A7 |

| Power Supply | 380V,50HZ,3-Phase or Customized |

| Control Method | Pendant Control; Remote Control;Cabinet Control |

Overview

The Rubber Tired gantry crane is a large gantry crane located in a container terminal for loading and unloading from container ships. It has stable performance, high efficiency and easy maintenance, and has appropriate safety instructions and overload protection devices, which can ensure the safety of operators and equipment to the greatest extent.

Rubber Tired gantry crane have great advantages, with higher reliability, lower maintenance and equipment costs, especially in ports with harsh coastal weather and more stability.

Advantages of Rubber Tired gantry crane

1. Novel structure, good usability;

2. Make full use of the storage yard, expand the working space and improve the work efficiency;

3. Good sealing, anti-corrosion, and durable;

4. It is employed to stack containers in container storage yards and is flexibly moved by its own rubber tyre for transshipping containers

5. Work Load: 20-800t; Span: 5-50m

6. Make full use of the storage yard, expand the working space and improve the work efficiency

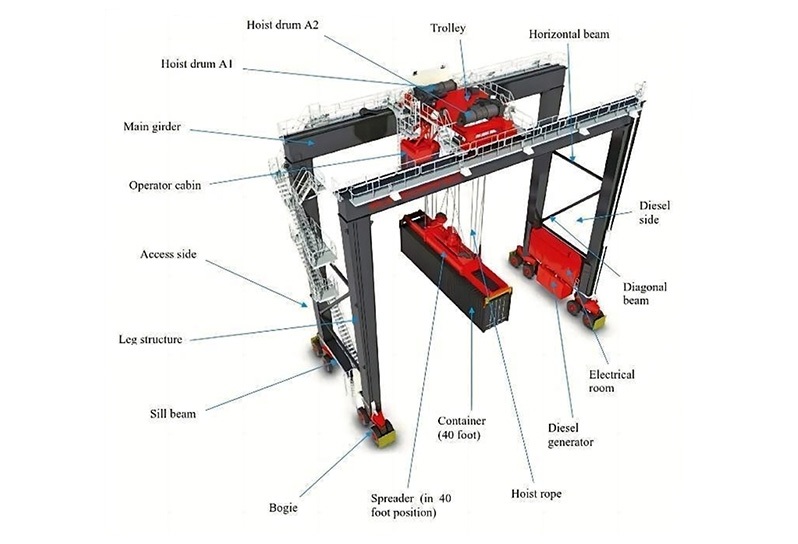

Structure of Rubber Tired gantry crane:

I. Main Structural System Gantry:

A rigid frame consisting of the main girder(s), legs, and end beams, forming the primary load-bearing structure of the crane.

II. Hoisting & Travel System Hoisting Unit:

Mounted on a trolley that moves along the main girder. It contains the motor, drum, and wire rope for lifting and lowering the spreader or hook.

Tire Travel System: Powered by electric motors driving heavy-duty solid rubber tires, providing full mobility within the container yard.

III. Power & Steering System Power Source:

Typically a diesel generator set for complete independence. Alternative options include cable reel systems (grid power) or hybrid/lithium battery solutions.

Hydraulic Steering: Allows versatile steering modes including straight-line, diagonal (crab), and 90-degree pivotal turning for precise positioning.

IV. Control & Safety System Control System:

Operated from a high-visibility cabin or via remote control. Utilizes PLCs and frequency inverters for smooth, precise, and automated motion control.

Safety Features: Standard equipment includes overload protection, travel limit switches, anti-collision systems, anemometers (wind speed monitors), and emergency stop functions.

Related Cases:

Henan Zhonggong Group Successfully Supplied 3 sets of Rubber Tire Gantry Cranes to Nigeria:

A large national factory in Nigeria purchased 3 European tire gantry cranes from Henan Zhonggong Group. The working conditions of the customer's factory are complex and the terrain structure is not stable. The stability of the crane during operation is very important. The rubber tire gantry cranes of Henan Zhonggong Group run smoothly and flexibly in the customer's factory. The 4 tire gantry cranes can rotate and lift in the same direction at the same time, which perfectly solves the customer's usage needs.

Application

Rubber tyred container gantry crane is employed to stack containers in container storage yards. It is flexibly moved by its own rubber tyres for transshipping containers.

Our Services:

Training:

Modular hands-on training programme

Highly qualified instructors and state-of-the-art equipment

Hands-on tasks to ensure that participants achieve all of their course goals

Training courses held at our training centre or locally

Installation:

Commissioning of crane installations

inspection and approval by our authorised crane inspectors

Spare Parts:

Fault analysis

Repairs carried out on site or at our Repair Center

Provision of genuine spare parts to replace damaged or defective parts

Recommendations for daily maintenance

Repair:

Genuine parts

Unsurpassed reliability

Long service life