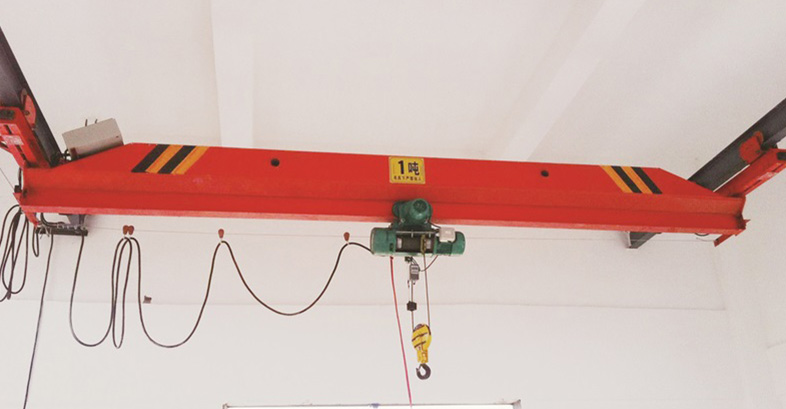

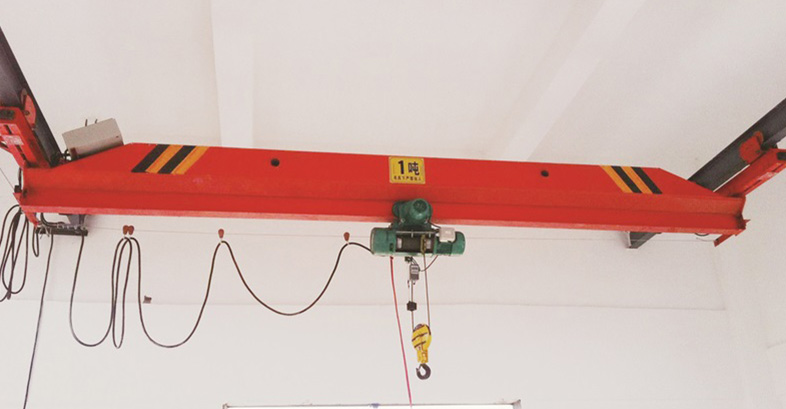

Monorial Crane

| Work Load(t) | 0.5-10t |

| Span | 3-25m |

| Lifting Height | 6-30m |

| Work Class | A3-A5 |

| Power Supply | 380V,50HZ,3-Phase or Customized |

| Control Method | Pendant Control; Remote Control |

Overview

Monorial Crane is a light and small material handling equipment. The whole set overhead crane is used with CD and MD type electric hoist, electric chain hoist, etc .It's usually used in the environment that the headroom is too samll to set the main girder and end truck of the crane.

Advantages of Monorial Crane

1. Monorial cranes are designed for flexibility and functionality, provide an ergonomic design that offers versatility and usability.

2. A monorial crane can be suspended directly from the overhead building structure without the need for interfering support columns.

3. For an under running system, the end trucks operate on the lower flange of the runway beams, the beams make up the crane runway, much lighter.

4. Monorial crane can easily operate even in very wide bays, this results in lower equipment costs and lighter design requirements in the building or supporting structure.

5. Another advantage to using an monorial crane system is that multiple under-hung crane runways can be installed adjacent to one another and operate simultaneously.

Accessories of Monorial Crane :

1、Metal structure components:

Including main girders and end girders. The main girder mostly adopts I-steel or a composite section of steel sections and steel plates. The end girder is used to connect the two ends of the main girder and support the entire crane structure.

2、Hoisting mechanism components:

Including electric hoists, steel wire ropes, pulleys, hooks, etc. The electric hoist is the core of the hoisting mechanism. The steel wire rope connects the hook, pulley block and drum, the pulley is used to guide the steel wire rope, and the hook is used to bear and lift the load.

3、Traveling mechanism components:

Mainly including wheel sets, motors, reducers, couplings, brakes, etc. The wheel sets are installed at the bottom of the end girders and run along the rails; the motor provides power, which is transmitted to the wheels through components such as reducers and couplings, and the brake is used to control the crane's stop.

4、Electrical control components:

Including wires and cables, remote controls, travel switches, control boxes, etc. Wires and cables are used to transmit electrical energy, remote controls and control boxes are used to operate the crane, and travel switches are used to limit the movement position or stroke of the crane.

5、Safety protection components:

Including overload limiters, bumpers, anti-unhooking devices, etc. The overload limiter can prevent the crane from operating overloaded, the bumper is used to reduce the impact force when the crane collides, and the anti-unhooking device can prevent the load on the hook from accidentally falling off.

Application

Monorial crane is a kind of small and lightweight overhead crane. It is widely applied in workshop of production and assembly lines, warehouse and other places to lift and move heavy loads. The underhung crane, as its name implies, is suspended from building roof structure and runs at the bottom flange of runway beam.

Our Services:

Full-chain crane solutions worldwide.

Tailored Solutions:

No one-size-fits-all products. We deliver cranes fully customized to your site, load, and regulations—optimized for safety and efficiency.

Global Export:

With 10+ years of export experience, we handle CE, ASME & other certifications, ensuring compliant and reliable delivery to 50+ countries.

Expert Installation:

Our qualified overseas team provides on-site installation and commissioning, following international standards for faster project launch.

Professional Support:

Backed by a global spare parts network, we offer remote support, maintenance, and training to ensure long-term, stable operation.