Free Standing Bridge Crane

| Work Load(t) | 0-3 |

| Span(m) | 0.7-12 |

| Lifting Height(m) | 3-12 |

| Work Class | A3-A5 |

| Power Supply | 380V,50HZ,3-Phase or Customized |

| Control Method | Pendant Control; Remote Control;Manual Control |

| Travelling mode | manual or electric |

Overview

Free standing bridge crane means combined crane, mainly composed of track, suspension device, walking trolley and some functional components. There are two types of free standing bridge crane, one is self-supporting KBK bridge crane and the other is free standing bridge crane. All modules are standard components, so any structure such as long and short distance single track, multiple tracks, curved track or circular track can be assembled. The main beam can also have one or more. The lifting device mainly adopts electric chain hoist, and some mechanical arms or welding guns can also be hung as tool slides.

Advantages of Self-supporting KBK Crane

1. The closed track design can effectively prevent dust from entering, thereby reducing the wear and tear of the trolley wheels and extending the service life.

2. The 2° slope design can effectively ensure that the car is in the center of the track and minimize sliding resistance.

3. The track is cold-rolled in one step without welding and has high strength.

4. It is light in weight, effectively reducing the pressure on structural support and significantly reducing costs.

5. Installed independently on the ground, no additional support is required. According to specific production needs, the extended load capacity can reach 2000kg and the span can reach more than 10m. Some track and trolley designs and modular designs are expandable. The rigid connection and unique guide wheel design can be easily operated manually to ensure that the movement is not diagonal, rocking, and stuck, improving precise positioning and reducing labor intensity for workers.

Advantages of Free Standing Bridge Crane

1、Efficient.Considerable cost and time savings. Simplified installation process before the system is put into use. In addition, the new KBK aluminum rail system requires even less maintenance than previous low-maintenance products.

2. Using the most advanced technology.In addition to its excellent technical performance, the independent crane aluminum rail system is also beautiful and stylish in appearance. This system is more suitable for modern production and user-friendly workstations.

3. Runs extremely smoothly

4. Installation is more convenient

5. Load capacity up to 3 ton

6. Ergonomically designed to make handling heavy loads easier

7. Lower noise levels

8. The system is almost maintenance-free

9. Two types of rails can integrate built-in sliding conductors

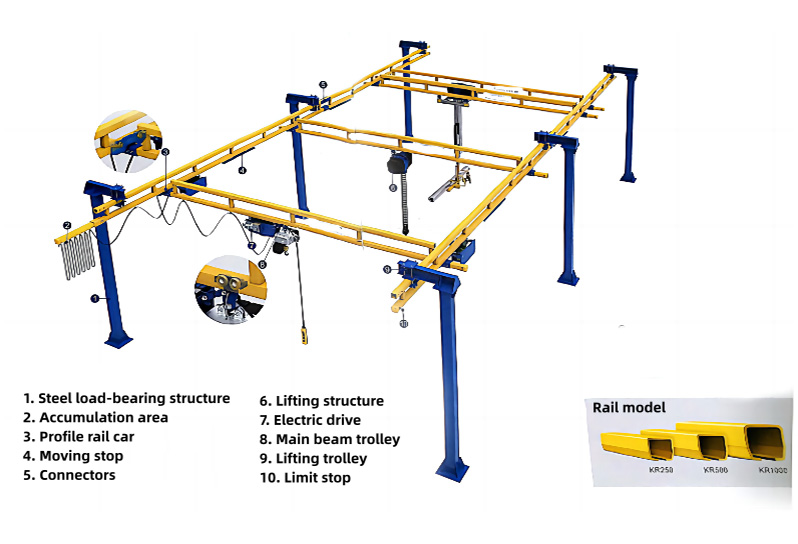

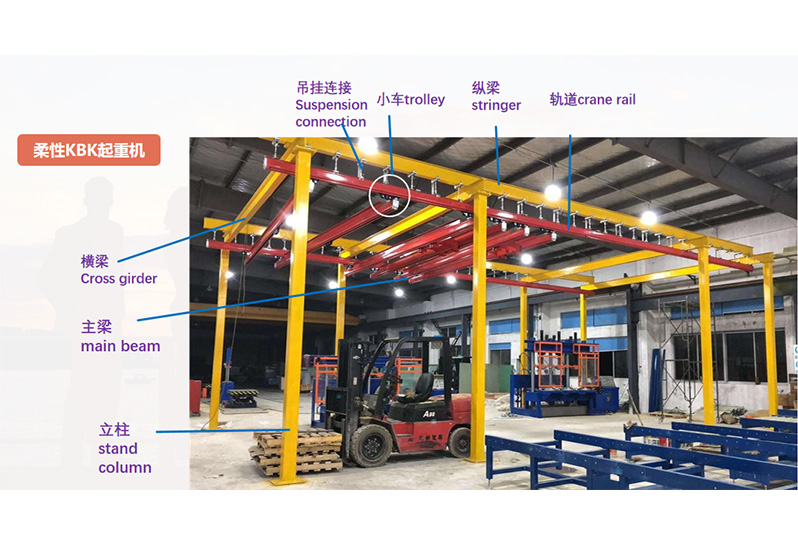

Structure of Self-supporting KBK Crane

Structure of Free Standing Bridge Crane

Accessories of KBK Bridge Crane:

1. KBK Rail System

Including enclosed track rails, suspension brackets, and connection joints. The modular KBK rail system ensures smooth trolley travel and flexible layout, suitable for various workshop structures.

2. Main Support Structure

Including suspension hangers, steel support frames, and fastening components. The structure is designed to securely fix the KBK rails to ceilings or supporting frames while allowing flexible installation.

3. Lifting Unit

Including electric chain hoist, load chain, hook, and hook safety latch. The hoist provides precise lifting and is ideal for frequent, light to medium-duty material handling.

4. Power & Control System

Including power supply lines, festoon systems, pendant control, and optional remote control, enabling safe and convenient crane operation.

5. Safety Components

Including end stops, overload protection, limit switches, and safety hooks to ensure reliable and safe operation during daily use.

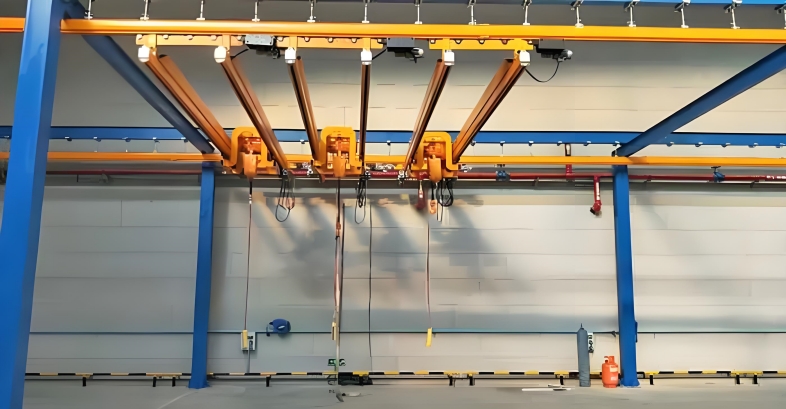

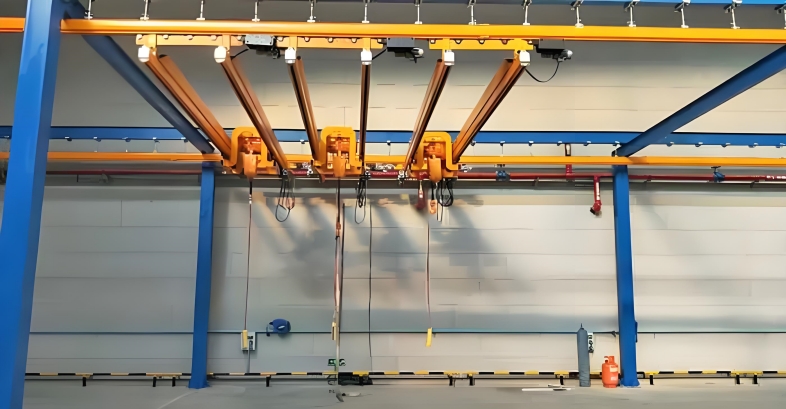

Relative Cases:

Russian customers visited to inspect and accept the KBK bridge crane they purchased from Henan Heavy Industry for their agricultural machinery assembly line.The visiting customer is a well-known Russian agricultural machinery equipment manufacturer with distribution offices in many countries around the world.

The customer visited our KBK bridge crane production workshop and our production process of rigid and flexible freestanding bridge cranes. Our customers are very satisfied with the quality and reliability of our products.

Application

It is especially suitable for areas with dense equipment, short transportation distance and high working frequency. It is widely used in the following industries: automobiles, shipbuilding, electronic assembly, food production, machinery production, warehouses, etc.

Our Services:

Training:

Modular hands-on training programme

Highly qualified instructors and state-of-the-art equipment

Hands-on tasks to ensure that participants achieve all of their course goals

Training courses held at our training centre or locally

Installation:

Commissioning of crane installations

inspection and approval by our authorised crane inspectors

Spare Parts:

Fault analysis

Repairs carried out on site or at our Repair Center

Provision of genuine spare parts to replace damaged or defective parts

Recommendations for daily maintenance

Repair:

Genuine parts

Unsurpassed reliability

Long service life