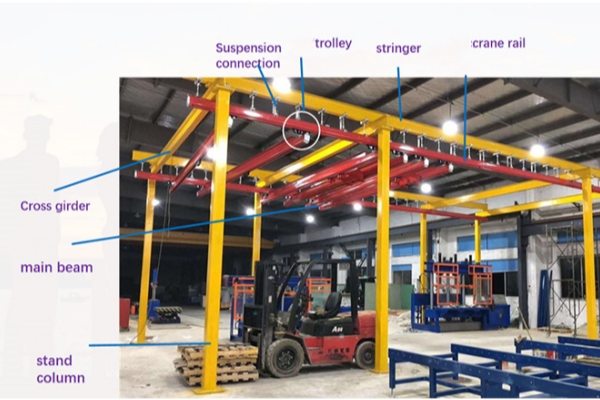

Free Standing Bridge Crane

| Work Load(t) | 0-3 |

| Span(m) | 0.7-12 |

| Lifting Height(m) | 3-12 |

| Work Class | A3-A5 |

| Power Supply | 380V,50HZ,3-Phase or Customized |

| Control Method | Pendant Control; Remote Control;Manual Control |

| Travelling mode | manual or electric |

Overview

Application

It is especially suitable for areas with dense equipment, short transportation distance and high working frequency. It is widely used in the following industries: automobiles, shipbuilding, electronic assembly, food production, machinery production, warehouses, etc.

Advantages of freestanding bridge crane compared with traditional crane

● Reduce factory building cost:The load-bearing design of the factory building column can be minimized and the factory building cost can be greatly reduced.

● No need to change the factory building:Existing workshops can be added at any time according to production needs without any modification to the factory building structure.

● Less idle equipment:According to the actual need to cover the transportation space, precise shooting can be carried out to minimize the waste of idle equipment.

● Modular design:Assembly and relocation are easy and quick, without affecting the normal use of the crane in other areas.

● More precise positioning:light and small structure, easy to operate, accurate positioning.

● Extremely low operating noise:simple structure, low failure rate, greatly reducing the risk of equipment failure.

● High comprehensive benefits:The track system is maintenance-free, the electrical components are easy to maintain, and the cost is low, reducing the time and labor costs caused by equipment failure, and the comprehensive benefits are high.

Specification

| Freestanding Bridge Crane Specification ( Customized ) | ||||||

| Work load(kg) | 125 | 250 | 500 | 1000 | 2000 | |

| Span(mm) | LK | 8500 | 7500 | 6000 | 5000 | 4000 |

| Total length(mm) | L | 9000 | 8000 | 7000 | 6000 | 5000 |

| Height (mm) | H | 808 | 878 | 948 | 1100 | 1200 |

| h | 335 | 335 | 335 | 365 | 365 | |

| Hanging(mm) | L1 | 470 | 470 | 525 | 585 | 645 |

| L2 | 100 | 100 | 100 | 250 | 250 | |

| Lifting Height(m) | 1-6 | |||||

| Operating mechanism | Lifting Speed(m/min) | 8/2 | 7.8/2.6 | 7.2/2.4 | 6.3/2.1 | 5.4/1.8 |

| Trolley | Manual/Electric | |||||

| Crane | Manual/Electric | |||||

| Crane work class | A4/A5 | |||||

| Type | Flexible Freestanding Bridge Crane | Self Supporting Bridge Crane | ||||

|

|

|||||

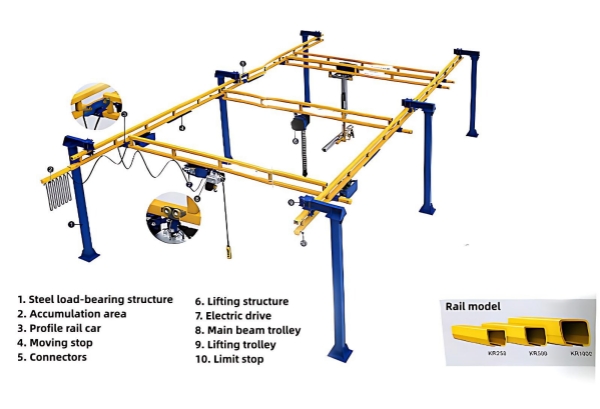

Choose the KBK crane type according to your needs

| Flexible Freestanding Bridge Crane Different Types | ||

Suspended flexible Suspended flexible |

Telescopic beam Telescopic beam |

Ring flexible Ring flexible |

|

● High-altitude and regional load transportation. |

● The main beam can extend beyond the width of the crane track in one or both directions, allowing for accurate lifting and placement of loads in inaccessible areas. |

● The route can be flexibly adjusted by combining straight and curved rails, switches and turntables. |

| Self Supporting Bridge Crane | |

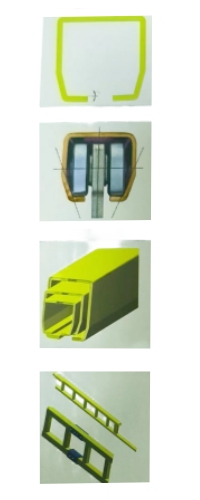

| Multiple series of track options | |

|

● With multiple series of track options, you can choose the most suitable product to minimize waste and save costs. ● Basic track: can be used in workshops where I-beams have been laid, or in workstations with limited space. ● Frame type: After special design and processing, the frame type track structure has been strengthened on the basis of the basic type, which can adapt to application conditions with larger loads and larger spans. The use of hanging points is greatly reduced, making the workshop layout more concise and beautiful, while reducing costs. ● Truss structure connection: The rails can be connected together using rail connections, making their installation and expansion more convenient and accurate. |

Case studies

|

Country: United States |

|

Country: Djibouti |

Our Service

|

Training Modular hands-on training programme Highly qualified instructors and state-of-the-art equipment Hands-on tasks to ensure that participants achieve all of their course goals Training courses held at our training centre or locally |

|

Installation Commissioning of crane installations inspection and approval by our authorised crane inspectors |

|

Spare Parts Fault analysis Repairs carried out on site or at our Repair Center Provision of genuine spare parts to replace damaged or defective parts Recommendations for daily maintenance |

|

Repair Genuine parts Unsurpassed reliability Long service life |

FAQ

Q: How can I choose right KBK cranes?

A: We have 24-hour online customer service to provide you with professional consulting services and help you choose the right Overhead Crane according to your working conditions.

Q: What do Henan Tosta Machinery do?

A: We design, manufacture, install overhead crane, gantry crane, free standing bridge crane, container handling crane, RTG crane, RMG crane, port crane and other crane components.

Q: Can you provide after sales service like installation and commission?

A: Yes. We have very professional installation teams not only in China but also many countries abroad like Russia, South Africa, South East Asia etc. Mainly of them have rich experience which can not only support the installation but also after sales service.

Q: Can you provide custom service?

A: Yes, of course. We are the manufacturer with about 40 years experience, and we have our own R&D team can design according to your special technical requirements. All the customized design will be finished within 3days after receiving your detail technical parameters requirements.

Q: How do you guarantee the quality?

A: We have very professional quality control team and complete quality control system like ISO. We will constantly check the quality during the manufacturing process, and strictly test the equipment before shipment. For each order, we will offer detail test report before shipment for your checking.

Q: How long is your delivery time?

A: For crane components, we will offer within 5 days; for light crane, the lead time will be about 10-15 days; For heavy duty crane, generally it will be about 30-45 days. And if you have very special requirement, the production period will be a bit long like 60 days or more. While if you have urgent requirement, we can also push our production and try to meet your requirements.

Q: How long is your warranty period?

A: Generally 12 months. It is also according to customers' requirements.