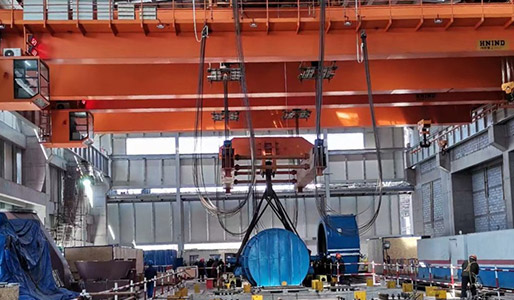

Billets Handling Crane

| Duty cycles (EN13001-1) | 1-2 million |

| Load spectrum(EN13001-1) | Q4-Q5 |

| FEM 1.0011998 | M7-M8 |

| Main trolley | Non-slewing tailored open winch |

| Lifting device | Slewing magnet beam |

| Main hoisting capacity | 15-40 tons |

| Span | 20-40 m |

| Uifting height,max. | 6-15 m |

| Bridge/Trolley travel speed | 60-150/20-60 m/min |

| Programmable Logic Controller(PLC) |

Standard |

| Manual/Automated control | Cabin |

| Bridge/Trolley power supply | Conductors/Festoon |

Overview

A slab and billet crane is a highly maneuverable electric overhead traveling (EOT) crane that transports large pieces of hot, soft metal - also known as slabs and billets - from the melt shop to its next destination. Because it is so hazardous, the melt shop is usually some distance away from other production locations. The crane feeds the slabs and billets into shaping rollers, takes the metal to be reheated in another furnace before shaping, moves the steel that has been shaped to another conveyor for further processing or delivers it to a storage area.

Advantages of Billets Handling Crane:

1.Precise and fast load handling with travelling speeds up to 150 m/min.

2.Heavy duty use with special, tailored slewing trolley.

3.Longer life and more return on investment as Tailored crane can run up to 8 million working cycles.

4.Wide range of lifting devices e.g. magnets, coil grabs hydraulic tongs can also be attached to the hooks to optimize load handling as per specific needs.

5.Reduced cycle times with semi-and fully automated functions.

6.Continuous availability of the systems 24 hours per day.

7.Energy savings due to Regenerative braking.

8.Simplified and minimized maintenance costs.

9.Reliable operation in harsh environmental conditions.

10.Remote service capability for fast problem solving and advance information for maintenance planning.

Application

Mainly used to lift and transfer steel plate, pipe, profile steel, steel bar, steel billets, steel coil, or large material in steel mill, shipyard, port yard, etc.